When we talk about laser engraving as a whole, it is seen as highly resourceful since it can make sure your products stand out and are as evident as ever.

However, what exactly are laser engravers, and how do they operate? These are just some of the questions that most people tend to ponder about. With that said, the article discusses laser engraving details, and just lasers can be operated to make all sorts of designs on wooden, metallic, and or plastic structures.

What is Laser Engraving?

To start, laser engraving is a process that uses a laser beam to cut or etch a design into the surface of an object. The laser beam is focused on forming an intense light that can be used to cut through materials such as wood, leather, and metal.

The laser beam is made up of millions of photons that are emitted in a tight pattern. When these photons hit the surface of the material, they leave behind small pits on the surface. This is what gives laser engraving its distinctive look. Laser engraving involves the use of a laser beam to create an image or text on a material.

The laser beam can be focused in one spot to make small marks, or it can be scanned across the surface of the material to make larger marks. The laser beam is usually controlled by computer software to cut out desired shapes in the material. The laser beam is then focused on the surface of the material, where it will start cutting out designs from it.

What are Lasers, and How Do They Operate?

Lasers are a type of coherent light, meaning that the waves are all in step with each other. This makes them very useful for many different purposes. Lasers can be used to detect objects and measure distances.

Lasers can also be used to produce high-quality images and videos. Lasers are also often used for cutting and engraving materials like wood or metal, as well as for etching or marking materials like plastics, paper, or glass. A laser is a device that creates light by emitting or amplifying electromagnetic waves in the form of a narrow beam.

The laser works by using an optical system to produce an intense, coherent beam of light. Now, lasers tend to become dangerous if they are not handled properly. This includes using lasers without proper safety equipment or training and pointing lasers at people without their consent.

The first laser was invented in 1960 by Theodore H. Maiman, who called his invention "a ruby laser." Invented in 1960, the first laser was made from a ruby crystal and used for doing scientific experiments and not for commercial applications. However, times have truly changed since then.

Are Lasers Dangerous in Any Way?

Lasers are beams of light that are used for many different purposes. They can be used to cut, drill, or engrave different materials. Lasers can be dangerous if they are not handled with care and knowledge. The dangers that lasers pose depend on the wavelength and power of the laser.

The shorter the wavelength, the more dangerous it is because it has a higher potential to do damage to human tissue. Lasers emit a beam of light that can cause eye damage if it is not handled properly. Lasers can also cause blindness if they are shone in someone's eyes for long periods of time.

Even so, lasers may not be dangerous if they're used with caution. In recent times, they have been used for different purposes. For example, lasers are used as pointers to cut metal, remove tattoos, and create holograms. We shouldn't be afraid of lasers either because they have a lot of benefits.

These benefits cannot be found in other types of light sources. They can help us with different tasks at home or at work. Furthermore, lasers are not harmful to humans in the way that they are commonly portrayed. The only time laser beams can be dangerous is when they are focused on a single point for an extended period of time.

How Do You Stop Lasers?

Lasers are used in many different industries and applications, including entertainment, medicine, science, and the military. Lasers are also used for laser cutting and laser welding. Moving on to stopping lasers, the initial step to stopping a laser is to identify the type of laser that you are dealing with.

There are three main types of lasers: gas lasers, solid-state lasers (which have no gas), and dye lasers. Gas lasers, for one, use an electric discharge through a gas to produce light at a specific wavelength or color. Solid-state lasers emit light from the stimulated emission of electrons from atoms or molecules in the crystal material that's been pumped with energy.

Dye lasers, on the other hand, use organic dyes as their lasing medium (the substance which produces the lasing). Lasers are a form of electromagnetic radiation that can be used for many purposes. They are produced by a process called stimulated emission, where photons of the same wavelength are emitted from atoms that have been excited.

The only major way to stop a laser is to use another laser with the same wavelength as the original one. This process of stopping lasers is called "heterodyning." Lasers can be used for many purposes, but they cannot be stopped without using an identical laser.

What are Laser Engravers?

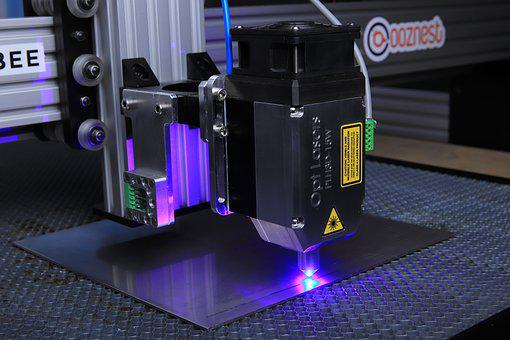

A laser engraver is a machine that uses a laser beam to etch or cut designs into an object. This process is most commonly used in the manufacturing industry to engrave logos and other designs onto metal products like jewelry, trophies, and awards.

Laser engravers are typically used for cutting and etching materials like wood, leather, rubber, acrylic, glass, stone, and metal. They may also be used for glass engraving or stone carving.

Laser engravers are often used in schools to create 3D models of objects for use in math classes or art projects. Laser engravers are the perfect choice for anyone who needs to cut materials like wood, leather, and other hard surfaces. They are also a great option for those who need to cut through metal or other dense materials.

The laser beam is focused on the material that needs to be engraved, and because of this, it can achieve a precision that is unmatched by any other type of cutting tool. It can create intricate designs and patterns with ease.

What's So Special About Laser Engravers?

Laser engravers can be used for anything from cutting logos into pieces of wood or making intricate designs in glassware. Laser engravers are a type of computer-controlled laser cutters that are able to cut through different types of materials. They are usually used for cutting and engraving wood, leather, plastic, rubber, and other soft materials.

A laser engraver is an essential tool for small businesses as it can help them save time on their projects. It can also be used to create intricate designs or logos that would take hours to do by hand. Laser engravers are the most modern and efficient way to engrave metal, wood, glass, and more.

Laser engraving, on the other hand, through engravers, is a process that uses a laser beam to create an image or text on a material such as metal, wood, glass, or plastic. The laser beam is focused on the surface of the material and burns an image into it. Unlike other traditional methods of engraving like sandblasting or water-jet cutting, laser engraving offers many benefits.

The biggest benefit of using laser engravers is that they are more precise than other traditional methods. Laser beams can be focused at very high levels of power, which means that they can cut through any material with ease. This precision also means that laser engraved items are less likely to have any imperfections or errors.

How Do Laser Engravers Work?

The laser engraver is a device that uses a laser beam to melt or vaporize the surface of a material and then uses the resulting gas pressure to deposit the material on the surface of another material. Laser engravers are used in various industries, including in manufacturing, construction, engineering, and design.

Laser engravers have the ability to make detailed cuts on a variety of materials, including wood, plastic, metal, and glass. Laser engravers work by using a laser beam to cut away material from the surface of a material. The laser is controlled by computer software that tells it where to cut and how deep to make the cut.

Laser engraving is a process that uses a laser beam to cut or etch patterns into a material. The laser beam is focused on the surface of the material, and this creates heat that either melts or vaporizes the material. This process can create beautiful and intricate designs in many different materials, such as wood, glass, plastic, metal, and stone.

Laser engravers work by cutting or etching patterns into a material using a laser beam. The laser beam is focused on the surface of the material, and this creates heat that either melts or vaporizes the material.

The Process of Laser Engraving: Explained

The process of laser engraving is a two-step process. The first step is to create the vector-based design that will be engraved onto the material. This can be done by hand or with a computer program. The second step is to engrave the design onto the material using a laser beam and a mirrored surface.

Does Laser Engraving Wear Off with the Passage of Time

In order for the laser engraving process to work, you need to have something with a mirrored surface on which you can project your design and something that can be engraved, like wood or metal.

Laser engraving is the process of using a laser beam to remove material from a surface. It is done by directing laser beams on the intended choice of material. The laser beam can be focused on a specific point of the material, and then it will heat up the area that has been focused on and make it either melt or vaporize.

Regardless of this, one of the biggest questions is whether or not laser engraving wears off with the passage of time. To answer this, when the material is removed, it leaves behind an etched design. Moreover, the laser engraving process is a type of additive manufacturing. This means that the material is added to the surface layer by layer.

The laser beam affects the surface of the material and creates a pattern on it. Due to this, it can be said that laser engraving does not wear off with the passage of time. It may wear off sometimes, but it depends on the type of material and the type of laser used in the process.

Can You Laser Engrave Metal Pens?

Laser engraving is a process that has been around for decades, but it has only recently become popular enough to be used on metal. The process involves the use of a laser to cut into the surface of the metal and engrave an image or text.

The lasers usually work by moving in a circular pattern and cutting into the surface of the metal. This leaves an engraved design on the surface. The laser engraving process is also done through the use of a laser to cut away the surface of the pen, leaving behind an engraved design.

Be it as such, if you're considering whether engraving a metal pen is possible, it completely depends on what type of metal you are trying to engrave. Metal pens can be engraved with a laser, but it will depend on what type of metal it is.

Can You Laser Engrave Wooden Pens?

Yes, you can laser-engrave wooden pens. There are some things to consider when laser engraving a wooden pen. The wood needs to be at least 1/4 inch thick and smooth. You also need to use wood that is strong enough for the process, like poplar or birch.

Wooden pens are a great way to make any gift more personal. They can be laser engraved with the recipient's name and the date of an event, or they can be engraved with a unique message.

It is possible to laser engrave wooden pens because they are made of wood which is a material that can easily be laser engraved. The process is done in two steps: first, the surface is cleaned using an abrasive tool, and then it is etched with a laser beam.

Laser engraving wooden pens take time and precision because it cannot be done quickly like other materials such as metal or plastic.

Intriguing Facts to Note About Laser Engraving?

Laser engraving has been around for decades and is a popular form of engraving. It is often used to engrave text on metal, glass, and or plastic. Laser engraving is a process that uses lasers to remove material from the surface of a material by burning it away. It is done by scanning the surface with a laser beam, which removes small amounts of material with each scan.

The first laser was created in the 1960s, and since then, there have been many innovations in laser technology. The most recent advancement in laser technology includes fiber lasers that can be used to engrave materials like plastics and rubber, as well as metals and glass.

In order to create a design for the laser engraving, an image needs to be created in vector form. The vector image will then be imported into the laser engraver software to create the design. Laser engraving is selectively heating material, usually metal or plastic, with a laser beam to the point where it becomes pliable.

The laser beam is focused on an area of the material and then moves across its surface. Lasers are one of the most versatile tools in the world. They can be used for everything from cutting metal to engraving wood to removing tattoos.

Things to Consider When Buying Your Own Laser Engraver?

As stated beforehand, the laser engraver is one of the most versatile and useful tools in the market today. It's not just for lasers; it can be used for wood, plastic, and even metal. It's a great tool to have in your workshop or garage because it can help you with a lot of projects. There are many things to consider when buying your own laser engraver.

You need to think about what you will be using it for and how often you will use it. You also need to think about what size machine you want because they come in different sizes. The more expensive machines offer more features, but if you're just looking for something simple, cheaper options will do the job as well.

There are a lot of things that you need to consider when buying your own laser engraver. The first factor to note is the power of the laser engraver. It's important to know how much power you need for your project. The second factor is the material that you want to engrave. It would be best to find out what materials are compatible with your laser engraver before you buy it.

Doing so is highly crucial so that you can be sure that your engraver will work adequately. The last factor is the size of your workspace and how much space you have available in your workshop or garage. You might also need to consider whether there are any safety hazards involved with using a laser, such as dust or fumes, in the area.

If you are interested, chek out MadeTheBest Laser Engravers.

Are Laser Engravers a Hefty Investment?

Laser engravers are an expensive investment. They can be anywhere from 1,000 to 10,000 dollars. The price depends on the size of the laser engraver and how much it can engrave per hour.

Some people think that laser engravers are a hefty investment because they cost a ton of money upfront. But if you look at it as an investment, you will see that they are actually a good bargain in the long run. Laser engravers last for years and years, which means that you won't have to buy another one for a long time.

Plus, if you use them for what they're intended for, then your return on investment is huge! Laser engraving machines have been on the market for a while now, though. For that reason, they are becoming more affordable. Laser engravers are a great investment for any business that is looking to make a big splash. They can be used for marketing, branding, and promotional purposes.

Laser engravers are not only useful for businesses but also for individuals who want to get their name out there. They are a great way to make your products stand out from the crowd and increase your sales. With its growing popularity, laser engravers might become more affordable in the times ahead. Check great laser engravers at an affordable price of MadeTheBest.

Should You Buy a New or a Used Laser Engraver for Your Business?

A laser engraver is a machine that is used to cut and engrave materials by using a laser beam. They are used in all sorts of industries, including sign making, product identification, and jewelry.

Onto the decision to buy a new or used laser engraver, it might be dependent on what the company needs it for. If the company does not need to do any heavy-duty work with their laser engraver, then buying a new one might be more cost-effective than buying a used one.

However, if the company needs to indulge in heavy-duty work, then it would be better to buy a used one. This is because older laser engravers typically have more power than new ones.

Conclusion

A laser engraver is a machine that can engrave any material. It can be used for both personal and professional purposes. The laser engraving machines are usually used to create logos, designs, and other images on different materials like wood, metal, plastic, etc.

Now, laser engravers can prove to be amazing machines, but they need to be handled with care. If not handled properly, they may lead to a fire or an explosion.

To avoid this from happening, you should never point the laser beam towards your skin or eyes and should always put the workpiece in a safe place before using it.

1 thought on “Everything You Need to Know About Laser Engraving”

alberto

buongiorno, ma vendete i prodotti della ortur che sembrerebbe una azienda che stia per chiudere? dico questo perché sono con un ticket aperto dal 29 agosto 2023 ed è da quella data che non rispondono più. Quindi o stanno fallendo o sono poco capaci … credo sia una di queste due opzioni